English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

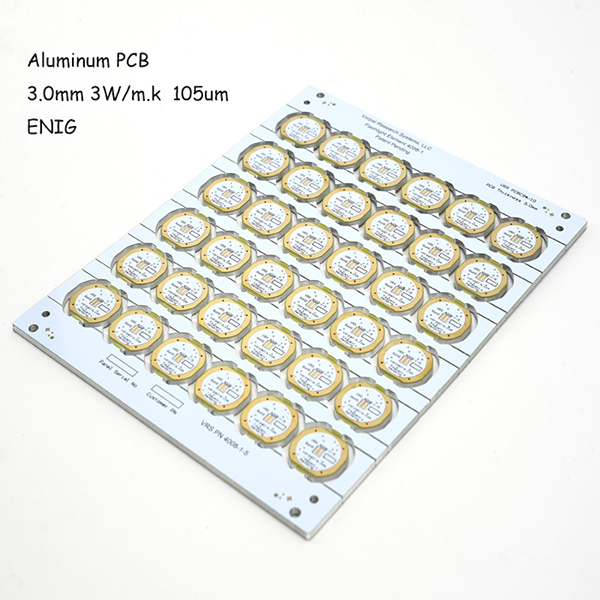

1 Layer Aluminum PCB

You can rest assured to buy Jiubao 1 Layer Aluminum Pcb from our factory. The metal core printed circuit board is a composite printed circuit board composed of a metal substrate, an insulating medium layer and a circuit copper layer. The metal matrix is usually aluminum, iron, copper, invar copper, tungsten-molybdenum alloy, etc.

Send Inquiry

Product Description

Metal Core PCB

Why Choose Metal Core for PCB Material?

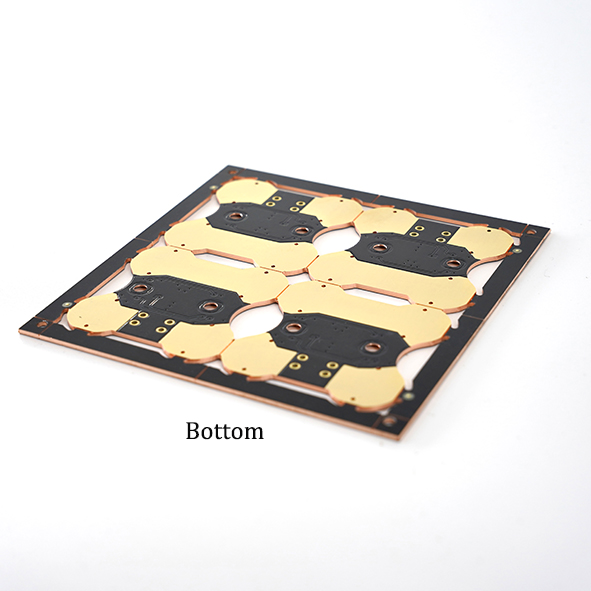

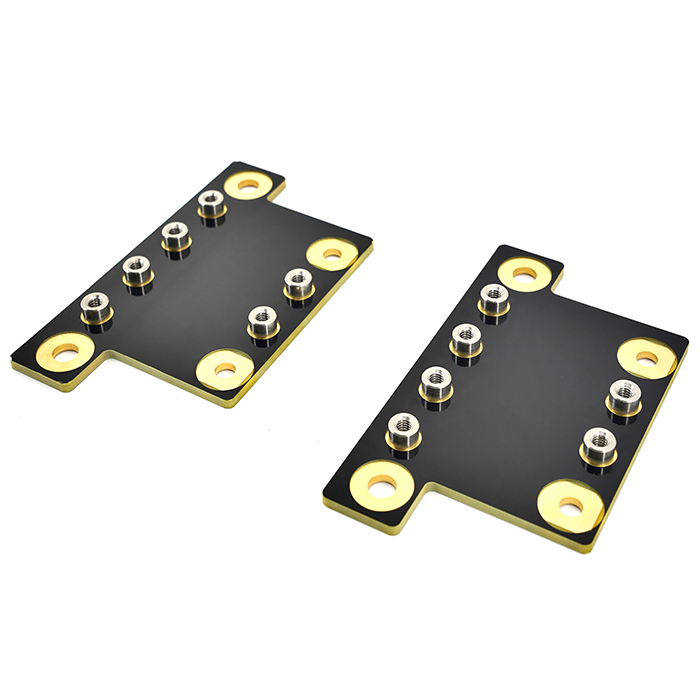

You can rest assured to buy Jiubao 1 Layer Aluminum Pcb from our factory. The metal core printed circuit board is a composite printed circuit board composed of a metal substrate, an insulating medium layer and a circuit copper layer. The metal matrix is usually aluminum, iron, copper, invar copper, tungsten-molybdenum alloy, etc. The heat dissipation of the metal substrate is higher than that of the copper clad laminate. The heat dissipation of the metal substrate is related to the density and thermal conductivity of its insulating layer. The thinner the insulating layer, the higher the thermal conductivity. The insulating layer is usually modified epoxy resin, polyphenylene ether, polyimide, etc. The thickness of the insulating layer is 50 μm-200 μm. The circuit layers consist of copper layers. The thickness of the metal plate is 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.0mm and 5.0mm. Like rigid-flex printed circuit boards, metal-based printed circuit boards can be divided into single-sided, double-sided and multi-layered, and are a special variety of printed circuit boards. Metal PCB is also known as metal core PCB, MCPCB, IMS (insulated metal substrate), metal clad PCB.

Metal Core PCB Substrates Are Classified According to Their Composition and Can Be Divided Into:

Aluminum base copper clad laminate

Iron base copper clad laminate

Copper base copper clad laminate

Steel base copper clad laminate

Iron base copper clad laminate

Copper base copper clad laminate

Steel base copper clad laminate

Metal-based Copper Clad Laminates Are Classified According to Their Characteristics and Can Be Divided Into:

General metal base copper clad laminate

Flame retardant metal base copper clad laminate

High heat resistant metal base copper clad laminate

High thermal conductivity metal base copper clad laminate

Ultra-high thermal conductivity metal base copper clad laminate

High frequency, microwave type metal base copper clad laminate

Multilayer metal base copper clad laminate

Flame retardant metal base copper clad laminate

High heat resistant metal base copper clad laminate

High thermal conductivity metal base copper clad laminate

Ultra-high thermal conductivity metal base copper clad laminate

High frequency, microwave type metal base copper clad laminate

Multilayer metal base copper clad laminate

Metal Core PCB Features:

a). Characteristics of aluminum: thermal conductivity of 237 W/(m·K), moderate cost, acceptable, and widely used.

b). The characteristics of copper: the thermal conductivity is 384 W/(m·K), the cost is too high, and it is used for high value-added products.

c). Characteristics of silver: thermal conductivity 429 W/(m·K),

d). Characteristics of iron: thermal conductivity 80W/(m·K),

e). Characteristics of steel: thermal conductivity 40W/(m·K),

b). The characteristics of copper: the thermal conductivity is 384 W/(m·K), the cost is too high, and it is used for high value-added products.

c). Characteristics of silver: thermal conductivity 429 W/(m·K),

d). Characteristics of iron: thermal conductivity 80W/(m·K),

e). Characteristics of steel: thermal conductivity 40W/(m·K),

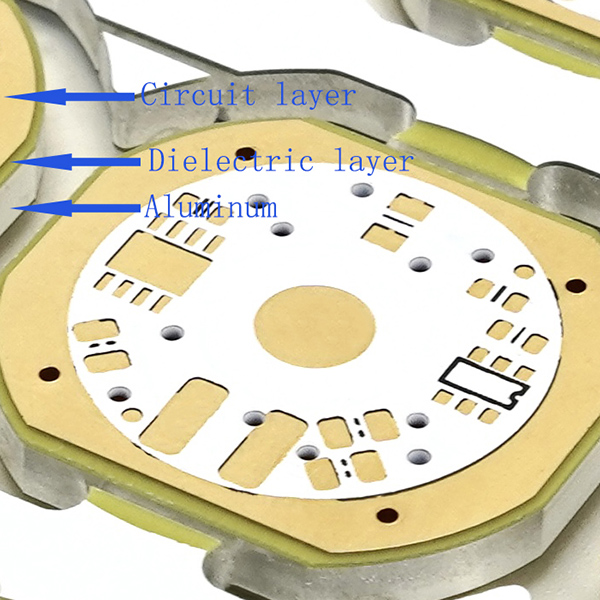

A metal PCB consists of a layer of copper foil, a dielectric layer, and a metal layer.

· Circuit copper layer: The copper layer used is thicker than normal CCL (1oz-10oz). Thicker copper layers mean greater current carrying capacity.

· Dielectric layer: The dielectric layer is a thermally conductive layer with a thickness of about 50μm to 200μm. It has low thermal resistance, heat transfer and insulation.

· Metal layer: The third layer is a metal layer, consisting of aluminum or copper, which has high thermal conductivity.

· Circuit copper layer: The copper layer used is thicker than normal CCL (1oz-10oz). Thicker copper layers mean greater current carrying capacity.

· Dielectric layer: The dielectric layer is a thermally conductive layer with a thickness of about 50μm to 200μm. It has low thermal resistance, heat transfer and insulation.

· Metal layer: The third layer is a metal layer, consisting of aluminum or copper, which has high thermal conductivity.

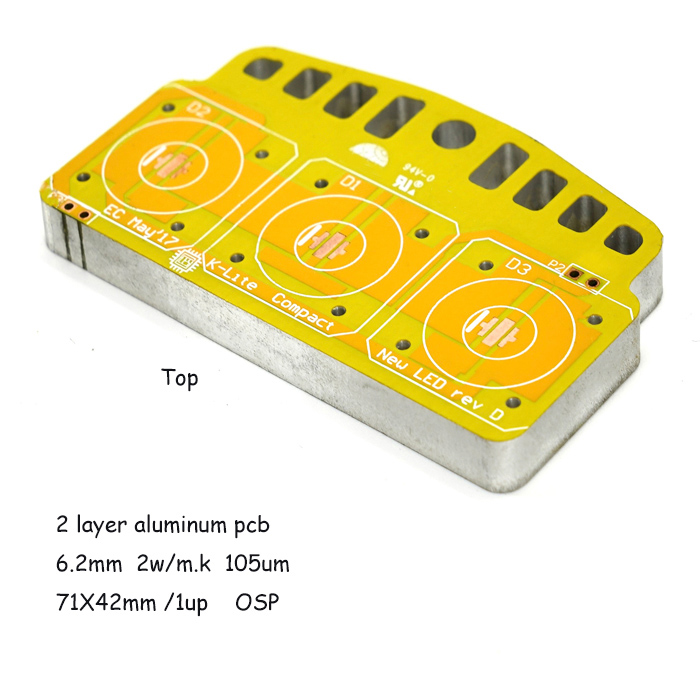

1-layer Aluminum Pcb

1-layer aluminum substrate product introduction:

The 1-layer aluminum pcb is an aluminum pcb board; the 1-layer aluminum pcb is divided into three layers: aluminum, insulating layer, and copper. Aluminum is for heat dissipation, the insulating layer is for heat transfer and insulation, and copper is for electrical conductivity. 1-layer aluminum pcb generally have printed circuits on one side and smooth wireless circuits on the other side. The most common aluminum pcb on the market are 1-layer aluminum pcb. The upper side is the circuit, and the lower side is connected to the shell or thermal adhesive for heat dissipation. The 1-layer aluminum pcb replaces the previous FR4 and PCB glass fiber board, which is strong and high-profile, has good heat dissipation, is not easy to break, and has good product structure flexibility. Jiubao Technology is a manufacturer with metal core PCB manufacturing process, a full set of high-end precision equipment 7S production workshop from material feeding to finished product packaging, employs high-quality elite team management, and has a strong professional team engaged in circuit board production , There are many outstanding engineers and professional managers. It is a professional aluminum pcb manufacturer with large scale, complete equipment, strict management and superior quality.

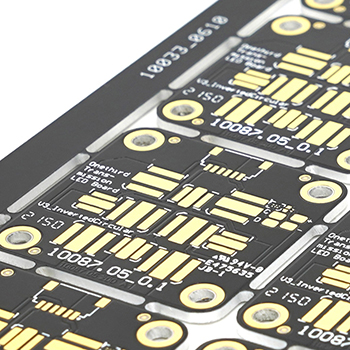

The 1-layer aluminum pcb is an aluminum-based copper clad laminate (a copper clad laminate is a substrate of a PCB). Aluminum PCBs are actually very similar to FR4 PCBs

The 1-layer aluminum pcb is an aluminum-based copper clad laminate (a copper clad laminate is a substrate of a PCB). Aluminum PCBs are actually very similar to FR4 PCBs

The Product Structure of 1-layer Aluminum Pcb is Shown in The Figure:

| Substrate | Aluminum |

| Plate thickness(mm) | 0.8~3.0mm |

| Maximum size(mm) | 1000X1500mm |

| Thermal conductivity (dielectric layer) | 0.8/1.5/ 2/3/5/8/12W/m.K. |

| Copper thickness(um) | 35;70;105;140-350um |

| Solder mask color | White;black;matte black;red;green;blue;matte green |

| Character Color | White/Black/Orange/Red/Blue |

| Forming method | CNC gong plate; CNC V cutting; mold forming; laser cutting and milling |

| Inspection test | AOI; high-speed flying probe; E-test; Voltage test |

| Surface treatment process | HASL ;FREE LEAD DNIG OSP |

| Delivery time | 2~3 days |

Heat dissipation: Aluminum PCB's performance in heat dissipation is quite good compared to ordinary FR4 PCB. For example, a 1.5mm thick FR4 PCB has a thermal resistance of 20-22 degrees per watt, while a 1.5mm thick aluminum PCB has a thermal resistance of 1-2 degrees per watt.

1-layer Aluminum Pcb Product Manufacturing and Production Process Manufacturing Instructions:

Thermal Expansion: Each substance has its own coefficient of thermal expansion. Aluminum (22ppm/C) and copper (18ppm/C) have very close CTEs. Since the aluminum PCB works well in terms of heat dissipation, there will be no serious expansion or contraction issues. Aluminum PCBs work great, durable and reliable.

Dimensional stability: Aluminum PCBs show dimensional stability and stable dimensions. For example, when they are heated from 30-140 degrees, their dimensions only change by 2.5%-3.0%.

· Others: Aluminum pcb can be used in surface mount technology for power devices. Aluminum PCB can be effectively used in circuit design due to its performance in terms of thermal expansion of circuit design. Aluminum PCBs help extend product shelf life and product power density. Aluminum PCBs are also very reliable. Aluminum PCBs can help reduce the overall size of the product and are also a cheaper option. Aluminum PCBs exhibit electromagnetic shielding and high dielectric strength.

Dimensional stability: Aluminum PCBs show dimensional stability and stable dimensions. For example, when they are heated from 30-140 degrees, their dimensions only change by 2.5%-3.0%.

· Others: Aluminum pcb can be used in surface mount technology for power devices. Aluminum PCB can be effectively used in circuit design due to its performance in terms of thermal expansion of circuit design. Aluminum PCBs help extend product shelf life and product power density. Aluminum PCBs are also very reliable. Aluminum PCBs can help reduce the overall size of the product and are also a cheaper option. Aluminum PCBs exhibit electromagnetic shielding and high dielectric strength.

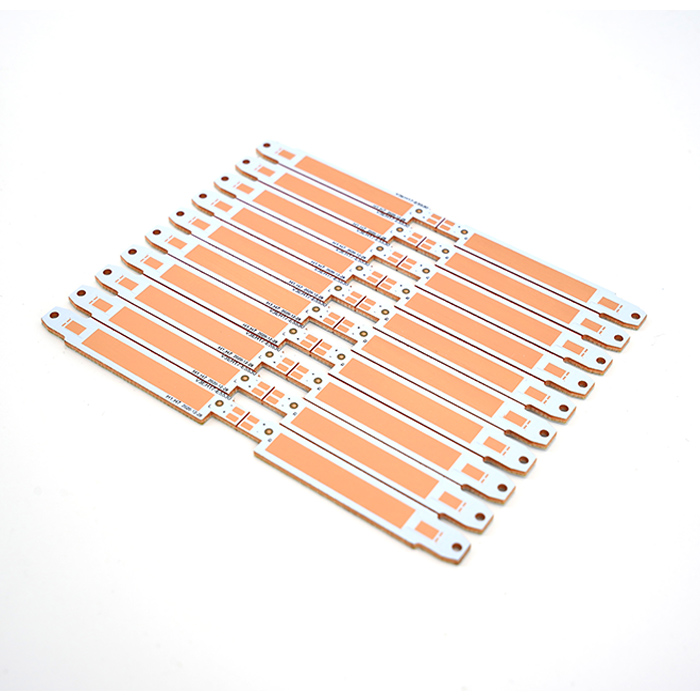

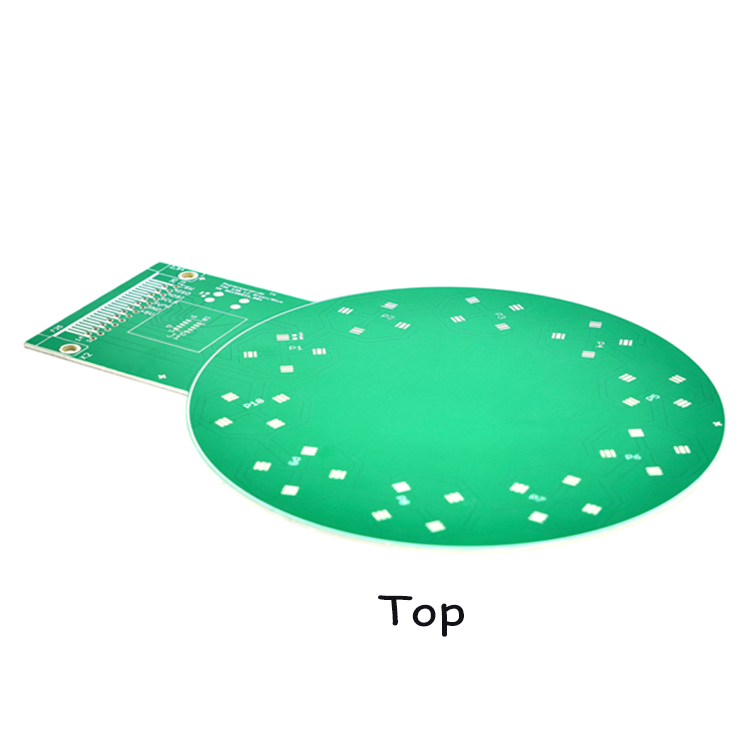

1-layer Aluminum Pcb Product Application Field:

Aluminum substrate pcb has excellent flame retardancy, high mechanical strength, dimensional stability, etc., especially good heat dissipation, electromagnetic shielding and floating tin properties. Widely used in motorcycles; igniters of mobile phones; high-power LEDs; speakers; power modules; acoustic shielding systems, etc.

Projection lamp; Street lamp; Plant growth lamp; LED lamp aluminum substrate; Projection equipment; Heat sink; Solar cell substrate;1-layer aluminum substrate used for 90% of underwater lights, suitable for 90% of lamps.

Aluminum PCB is an ideal solution for high-density and high-power products such as LED applications, power equipment, computers, etc.

If you have thermal issues in your PCB design, aluminum should be your first consideration. JBPCB provides all kinds of aluminum substrates, including single-sided aluminum substrates, multi-layer aluminum substrates, hybrid aluminum substrates, flexible aluminum substrates, through-hole aluminum substrates, etc. Other categories, such as general-purpose aluminum substrates, high thermal conductivity aluminum substrates, and high-frequency aluminum PCBs are also available. If you need more details about our aluminum PCBs, please feel free to contact us.

Projection lamp; Street lamp; Plant growth lamp; LED lamp aluminum substrate; Projection equipment; Heat sink; Solar cell substrate;1-layer aluminum substrate used for 90% of underwater lights, suitable for 90% of lamps.

Aluminum PCB is an ideal solution for high-density and high-power products such as LED applications, power equipment, computers, etc.

If you have thermal issues in your PCB design, aluminum should be your first consideration. JBPCB provides all kinds of aluminum substrates, including single-sided aluminum substrates, multi-layer aluminum substrates, hybrid aluminum substrates, flexible aluminum substrates, through-hole aluminum substrates, etc. Other categories, such as general-purpose aluminum substrates, high thermal conductivity aluminum substrates, and high-frequency aluminum PCBs are also available. If you need more details about our aluminum PCBs, please feel free to contact us.

FAQ

Q1: What is the minimum order quantity for MCPCB?

A1: Our MCPCB MOQ varies with different items, support order from 1pcs.

Q2: What documents should we provide?

A2: PCB: Gerber files are better, (Protel, power pcb, PADs files), PCBA: Gerber files and BOM list.

Q3: What information do I need to provide besides documents?

A3: Quotation requires the following specifications:

a) Substrate:

b) Plate thickness:

c) Copper thickness:

d) Thermal conductivity:

e) Surface treatment:

f) Color of solder mask and silk screen

g) Quantity

Q4: Can metal core PCBs be designed with charged DIP components through metal holes?

A4: Yes. We are a professional metal core PCB circuit board manufacturer, we have many years of production experience, you can see our insulation hole aluminum PCB details

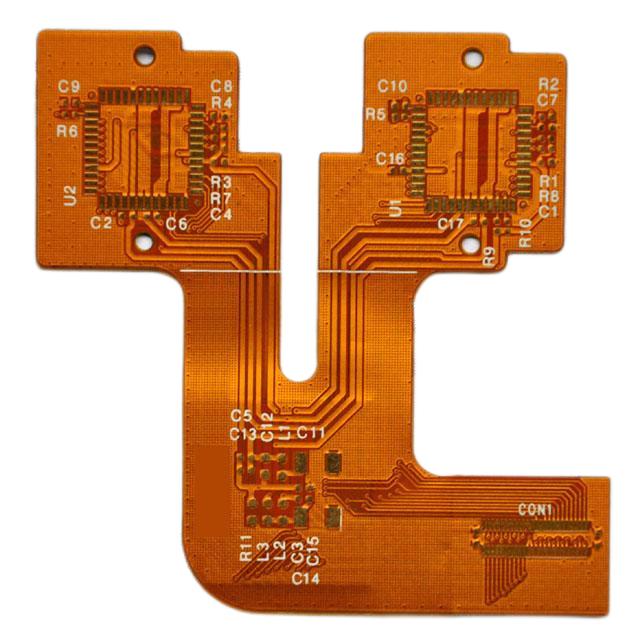

Q5: Can we make the craft of the following picture?

A5: Yes, it's OK to draw what you want.

Q6:What are the time and environment requirements for metal core PCB storage?

A6:The temperature and humidity of metal core PCB storage will affect the life of the product. Under the vacuum plastic film packaging, the temperature is 25±2℃; the humidity is 55±5% RH, and the quality is guaranteed for 6 months. If the vacuum plastic film packaging has been removed or stored for more than 6 months, it is recommended to bake at 150°C/1 hour before production.

A1: Our MCPCB MOQ varies with different items, support order from 1pcs.

Q2: What documents should we provide?

A2: PCB: Gerber files are better, (Protel, power pcb, PADs files), PCBA: Gerber files and BOM list.

Q3: What information do I need to provide besides documents?

A3: Quotation requires the following specifications:

a) Substrate:

b) Plate thickness:

c) Copper thickness:

d) Thermal conductivity:

e) Surface treatment:

f) Color of solder mask and silk screen

g) Quantity

Q4: Can metal core PCBs be designed with charged DIP components through metal holes?

A4: Yes. We are a professional metal core PCB circuit board manufacturer, we have many years of production experience, you can see our insulation hole aluminum PCB details

Q5: Can we make the craft of the following picture?

A5: Yes, it's OK to draw what you want.

Q6:What are the time and environment requirements for metal core PCB storage?

A6:The temperature and humidity of metal core PCB storage will affect the life of the product. Under the vacuum plastic film packaging, the temperature is 25±2℃; the humidity is 55±5% RH, and the quality is guaranteed for 6 months. If the vacuum plastic film packaging has been removed or stored for more than 6 months, it is recommended to bake at 150°C/1 hour before production.

Hot Tags: 1 Layer Aluminum PCB, China, Factory, Manufacturers, Suppliers, Price, Made in China

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Related Products

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy