English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

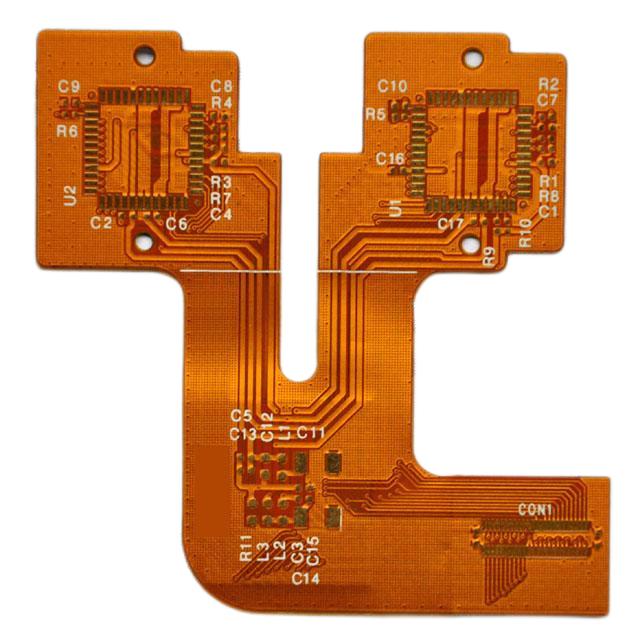

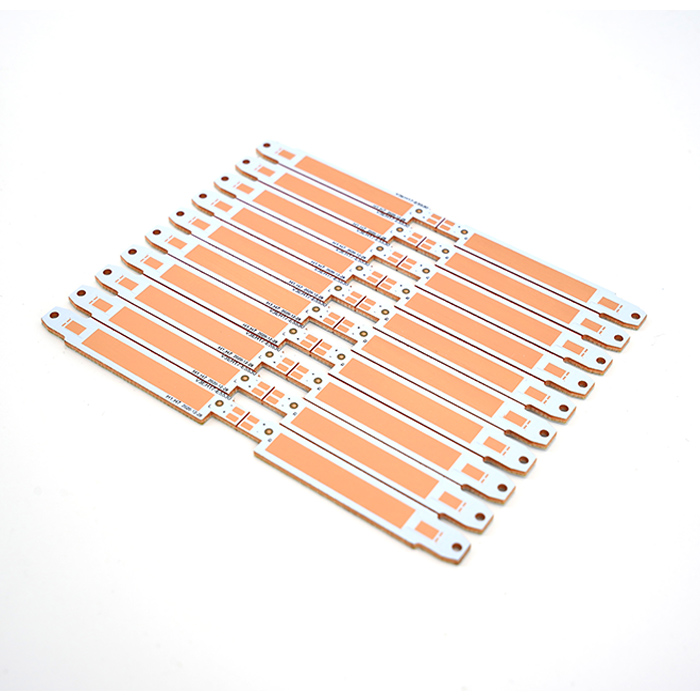

FPC flexible PCB

FPC flexible PCB has a wide range of applications, including consumer electronics, automotive electronics, medical equipment, aerospace and other fields, JBpcb is a high-quality supplier of FPC flexible PCB made in China, if you want to customize FPC flexible PCB, please contact us and get Our factory quotation.

Send Inquiry

FPC flexible PCB is a circuit board made of flexible substrates, which are highly bendable and foldable. FPC flexible PCB is usually composed of multi-layer film substrates and conductive layers. Its main feature is the bendability and foldability of the circuit board, so it is suitable for electronic devices that need to be bent or folded. FPC flexible PCB has many advantages, such as small size, lightweight, high reliability, etc., so it has been widely used in many fields, such as mobile phones, digital cameras, tablet computers, automotive electronics, medical equipment, etc. In short, FPC flexible PCB is a very important electronic component. Its appearance makes the design of electronic equipment more flexible and diverse and also provides more choices for the manufacture of electronic equipment.

2. The production process of FPC flexible PCB

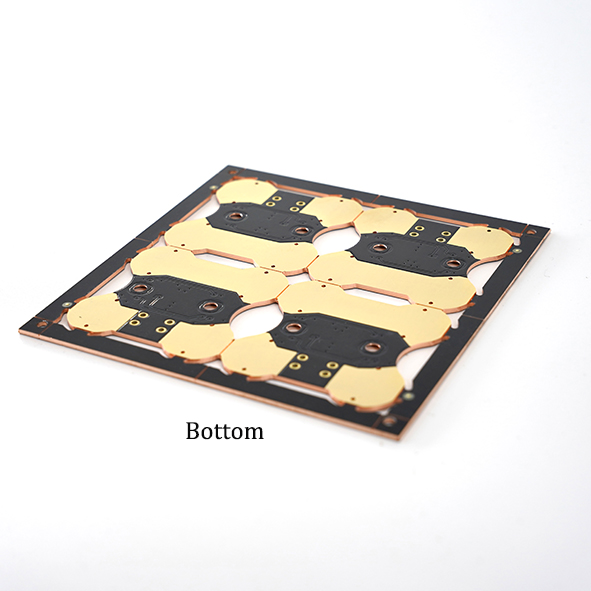

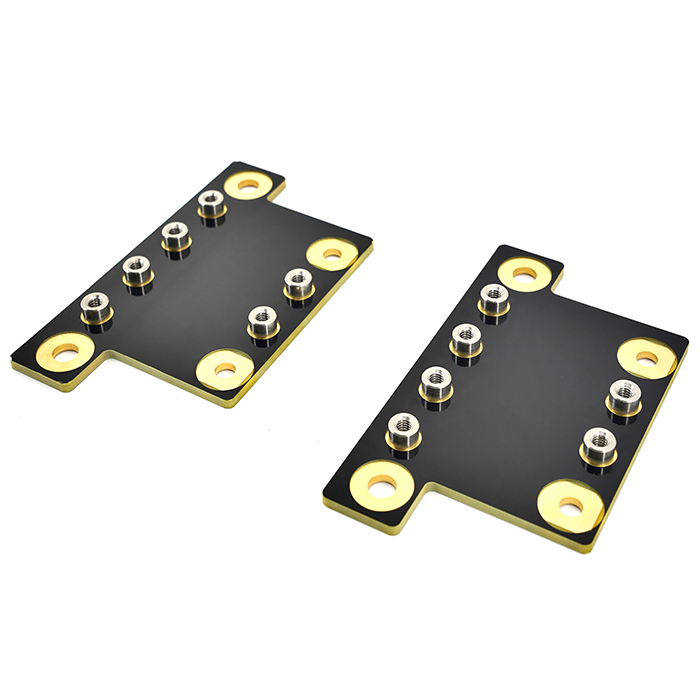

FPC flexible PCB has flexibility and reliability. At present, there are 4 types of FPC flexible PCBs in the market: single-sided (1 layer), double-sided (2 layers), multi-layer and soft-hard PCB. The production process of FPC flexible PCB mainly includes the following steps: first, base material preparation, usually polyimide film or polyester film is used as the base material, and the basic material of flexible PCB is prepared by printing, copper cladding, and other processes; secondly It is graphics production. According to the circuit board design drawing, the circuit pattern is made on the substrate by photolithography or laser cutting technology; then electroplating, a layer of metal is plated on the circuit by electroplating technology, such as copper, nickel, Gold, etc., to increase conductivity and corrosion resistance; finally, cutting and testing, the finished flexible PCB is cut according to the required size, and tested and inspected to ensure that its quality and performance meet the requirements. In general, the production process of FPC flexible PCB is relatively complicated, requiring the cooperation of various processes and fine operations, but its flexible performance and miniaturization characteristics make it widely used in electronic products.

How to make FPC flexible PCB?

1-layer FPC flexible PCB manufacturing process:

Cutting-drilling-dry film-attachment-exposure-development-etching-peeling surface treatment-covering film-pressing-curing surface treatment-nickel gold deposition-character printing-shearing-electrical measurement-punching-final inspection -Packing and shipping

2-layer FPC flexible PCB manufacturing process :

Cutting -Drilling-PT H -Electroplating- Pretreatment - Pasting Dry Film- Parasite Exposure - Development -Graphic Electroplating-Removing Film- Pretreatment - Pasting Dry Film- Planning Exposure - Development -Etching-Removing Membrane-Surface Treatment-Laminating Film-Lamination-Curing- Nickel Plating-Character Printing- Cutting -electric test-stamping-final inspection - packing - shipping。

FPC PCB process capability:

|

Flex Material |

Taihong, Shengyi, Lianmao |

||

|

PCB Material |

KB , Shengyi, Lianmao |

||

|

Copper Thickness |

12um-70um |

||

|

Surface finish |

|

||

|

Surface finish Thickness

|

E NIG |

Ni Au |

2-4um _ _ |

|

0.025-0.075um _ |

|||

|

ENEPIG |

Ni _ Au PD |

2-4um _ _ |

|

|

0.025-0.075um _ _ |

|||

|

0.025-0.075um _ |

|||

|

Electric Gilding

|

Ni AU |

2-4 um |

|

|

0.05-0.35um |

|||

|

RF-PC Thickness Minimum(mm)

|

4 layers of hardboard + 2 layers of soft board

|

0.6 mm |

|

|

6 layers of hardboard + 2 layers of soft board |

0.6 mm |

||

|

RF-PC Thickness Tolerance

|

4 layers of hardboard + 2 layers of soft board |

0.1 mm |

|

|

6 layers of hardboard + 2 layers of soft board |

0.1 mm |

||

|

Width / Space Minimum(mm)

|

4 layers of hard board + 2 layers of soft boardWidth / Space Minimum(mm) |

1oz |

0.075mm |

|

1/2oz |

0.06mm |

||

|

1/3oz |

0.05mm |

||

|

Width / Space Minimum(mm)

|

4 layers of hard board + 2 layers of soft boardWidth / Space Minimum(mm) |

1oz |

0.075mm |

|

1/2oz |

0.06mm |

||

|

1/3oz |

0.05mm |

||

|

6 layers of hard board + 2 layers of soft boardWidth / Space Minimum(mm) |

1oz |

0.075mm |

|

|

1/2oz |

0.06mm |

||

|

1/3oz |

0.05mm |

||

|

Drill Minimum(mm) |

Drill |

∮0.1 mm |

|

|

Laser |

∮0.075 mm |

||

|

Shift Tolerance |

Coverlay |

0.1 mm |

|

|

SUS |

0 .15 mm |

||

|

P I |

0 .1 mm |

||

|

FR-4 |

0 .15 mm |

||

|

EMI FILM |

0.1 mm |

||

|

Coverl ay (PI & adhesive )

|

12.5 um -50 um |

||

|

12.5 um -75 um |

|||

|

Coverlay overflow glue amount |

0.02 -0.03 mm |

||

3. Features of FPC flexible PCB

FPC flexible PCB is a flexible circuit board used in electronic equipment, consisting of a flexible substrate and copper-clad foil. Compared with traditional rigid PCB, FPC flexible PCB has the following characteristics:

a). Flexibility: FPC flexible PCB can be bent, folded, and twisted to adapt to various complex three-dimensional shapes, which can greatly reduce the volume of equipment and improve the reliability of equipment.

b). Thin and light: FPC flexible PCB has a very thin thickness, which can reach less than 0.1mm, which is very suitable for use in thin and light devices.

c). High density: FPC flexible PCB can realize high-density wiring, and can realize the layout of multi-layer circuits in a very small space, which improves the performance and reliability of electronic equipment.

d). High-temperature resistance: FPC flexible PCB can withstand high temperatures, can work normally in high-temperature environments, and is suitable for some electronic equipment in high-temperature environments.

e). Corrosion resistance: FPC flexible PCB has good corrosion resistance and can be used in harsh environments. In short, FPC flexible PCB has many advantages, can meet the needs of various electronic equipment, and is a very important electronic component.

FPC flexible circuit board (Flexible Printed Circuit Board) is a circuit board made of flexible substrates. Its main characteristics are good flexibility and bendability, and it is suitable for various complex three-dimensional space layouts. FPC flexible circuit boards have a wide range of applications, including consumer electronics, automotive electronics, medical equipment, aerospace, and other fields. In the field of consumer electronics, FPC flexible PCBs are widely used in electronic products such as smartphones, tablet computers, and notebook computers. Compared with traditional rigid PCBs, FPC flexible PCBs have better reliability and anti-interference, and can achieve smaller, lighter, and thinner designs. In the field of automotive electronics, FPC flexible PCBs are mainly used in automotive dashboards, car audio, navigation systems, and other equipment. Due to the high reliability and durability requirements of automotive electronic equipment, the high-temperature resistance and vibration resistance of FPC flexible PCB has been widely recognized. In the field of medical equipment, FPC flexible PCB is mainly used in medical monitoring equipment, surgical instruments, and other equipment. Because FPC flexible PCB has good flexibility and bendability, it can better adapt to the curve of the human body, so it is more and more widely used in medical equipment. In short, FPC flexible PCB is a circuit board with wide application prospects, which has unique advantages and application value in various fields.