English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

HDI PCB

HDI PCB products have a wide range of applications and are not used in general products. They are only used in special high-end products and circuits that require precision, such as consumer electronics, smart home, communication 5G, aviation, GPS navigation, medical, industrial control, automotive, semiconductor, and automotive industry.

Send Inquiry

Product Description

HDI PCB Product Details:

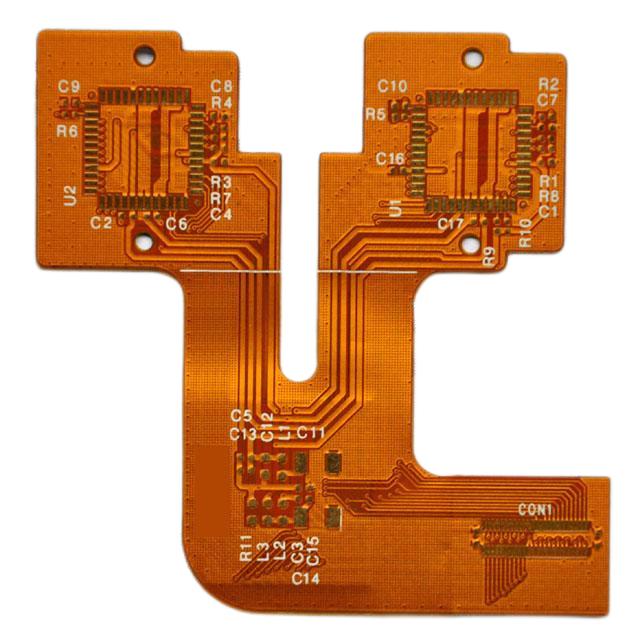

HDI (High Density Interconnector) PCB is a relatively high line density printed circuit board using micro-blind and hidden technologies. The HDI PCB has an inner layer circuit and an outer layer circuit, and then uses drilling, through-hole plating and other processes to realize the internal connection of each circuit layer.

HDI PCB is usually produced by lamination method, the more lamination times, the higher the technical quality of HDI PCB. Ordinary HDI PCB is mainly one-time assembly, high-tech HDI PCB uses two or more assembly technologies, and adopts advanced HDI PCB technologies such as stacking, electroplating and direct laser drilling.

When the density of HDI PCB exceeds eight-layer board, the production cost of HDI PCB will be lower than the traditional and complex lamination process. HDI PCB promotes the use of advanced packaging technology, and its electrical performance and signal accuracy are higher than traditional PCBs. In addition, HDI PCB has the best improvements for high frequency interference, electromagnetic wave interference, electrostatic discharge, thermal conductivity, etc.

Electronic products are constantly developing towards high density and high precision. The so-called "high" not only improves the performance of the machine, but also reduces the size of the machine. High Density Integration (HDI) technology enables greater miniaturization of end product design while meeting higher standards of performance and electronics efficiency. At present, many popular electronic products such as mobile phones, digital (photo) cameras, laptops, automotive electronics, etc. use HDI PCB . With the update of electronic products and market demand, HDI PCB development will be very fast.

HDI PCB is usually produced by lamination method, the more lamination times, the higher the technical quality of HDI PCB. Ordinary HDI PCB is mainly one-time assembly, high-tech HDI PCB uses two or more assembly technologies, and adopts advanced HDI PCB technologies such as stacking, electroplating and direct laser drilling.

When the density of HDI PCB exceeds eight-layer board, the production cost of HDI PCB will be lower than the traditional and complex lamination process. HDI PCB promotes the use of advanced packaging technology, and its electrical performance and signal accuracy are higher than traditional PCBs. In addition, HDI PCB has the best improvements for high frequency interference, electromagnetic wave interference, electrostatic discharge, thermal conductivity, etc.

Electronic products are constantly developing towards high density and high precision. The so-called "high" not only improves the performance of the machine, but also reduces the size of the machine. High Density Integration (HDI) technology enables greater miniaturization of end product design while meeting higher standards of performance and electronics efficiency. At present, many popular electronic products such as mobile phones, digital (photo) cameras, laptops, automotive electronics, etc. use HDI PCB . With the update of electronic products and market demand, HDI PCB development will be very fast.

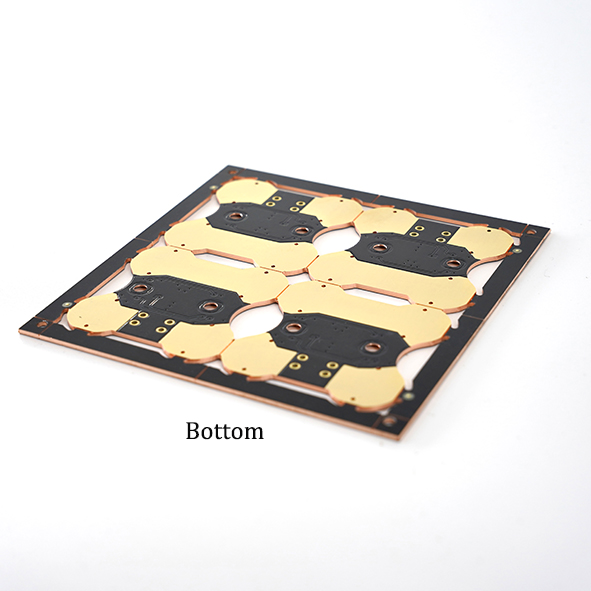

HDI PCB Structure Diagram:

HDI PCB is a high-density interconnect printed circuit board. Boards covered with blind holes and then recast are HDI printed circuit boards. It is divided into first order, second order, third order, fourth order and fifth order plates. Order HDI board. For example, the iPhone 6 motherboard is a 5th order HDI board

The HDI board has 10 layers and 8 layers, and the dense peripheral layers are like a web. The internal structure of the HDI board uses 3D graphics to display the internal structure of the board circuit of various laminated structures.

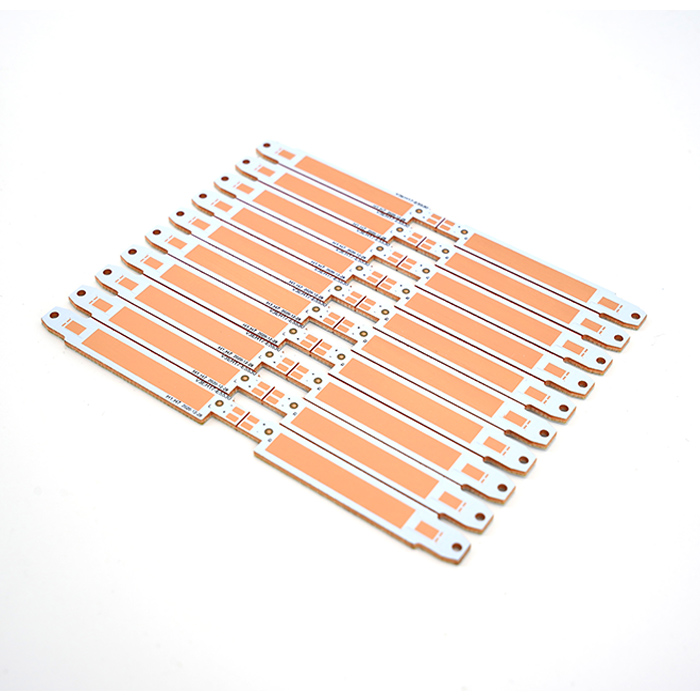

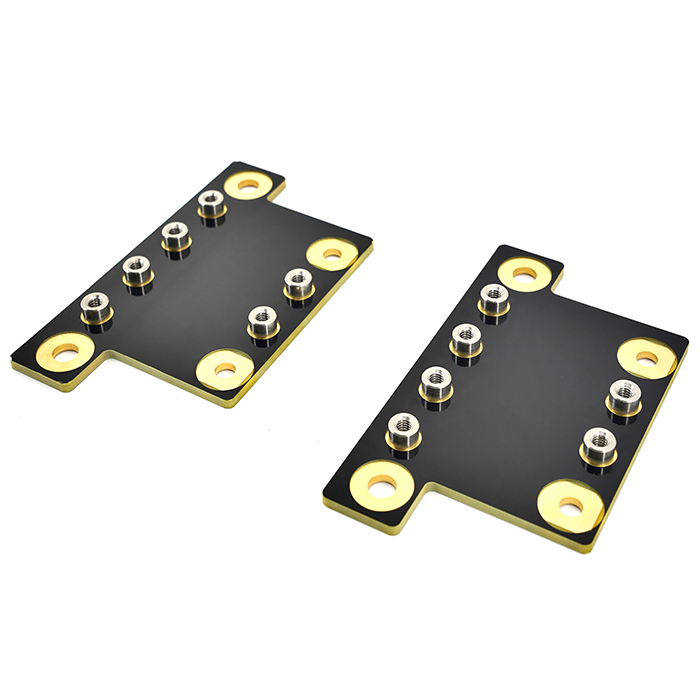

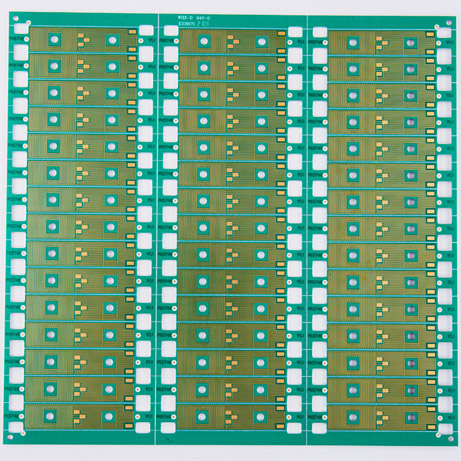

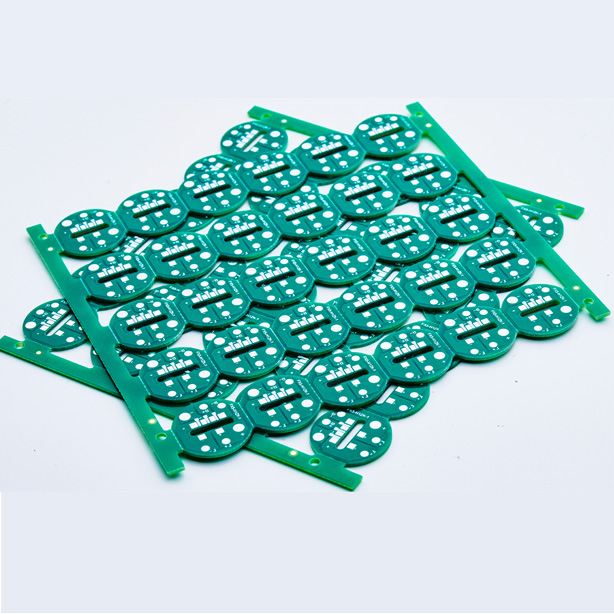

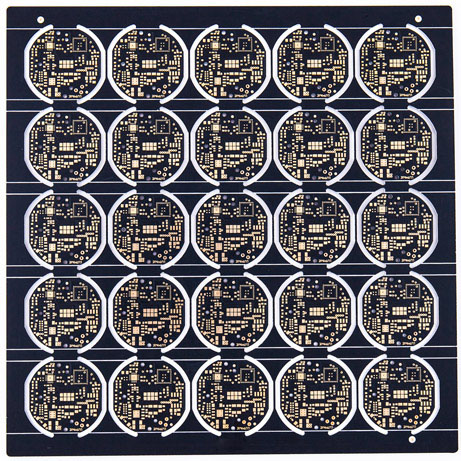

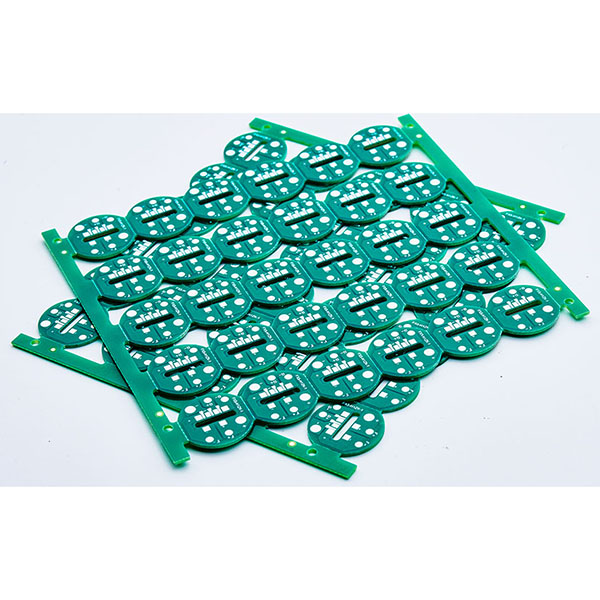

Front and Back View of HDI PCB Products:

HDI Board and Manufacturing Process :

| Material: | Rogers+FR4, High TG FR4, Teflon |

| Layers: | 2-40l |

| Thickness (mm) | 1.0-5.0 |

| Order: | Level 1 - Level 6 |

| Copper thickness | 35UM-140UM |

| Minimum line width | 0.065 mm |

| Minimum aperture | 0.1 mm |

| Solder mask color | white/black/matt black/red/green/blue/matt green |

| character color | red/black/orange/red/blue |

| Forming method | CNC gong, CNC V cut, mold making, laser cutting and milling |

| Control exam | AOI, high speed flying probe, electronic test, voltage test |

| Surface treatment process | Chemical Immersion Gold, Chemical Nickel Palladium Gold, OSP, Aerosol Tin |

| delivery date | 6-10 days |

Application of HDI PCB Products:

HDI PCB products have a wide range of applications and are not used in conventional products. They are only used in special high-quality products and circuits that require precision, such as: consumer electronics, smart home, 5G communications, aviation, GPS navigation, medical, industrial control, automotive, semiconductor, automotive.

Advantages of HDI PCB Products:

It can increase the wiring space, and the small space carries tight lines, which realizes the superiority of product intelligence in people's demand for exquisite products.

Frequently Asked Questions:

Q1: What are the board requirements for HDI PCB production?

A1: We are a professional HDI PCB manufacturer. We have many years of experience in PCB manufacturing. We check the quality of incoming materials layer by layer to ensure product quality. We have long-term cooperative brand suppliers such as Shengyi, Lianmao, Taiyao, Rogers.... The production process strictly controls each process and complies with international PCB quality system standards.

Q2: Can you specify the materials for PCB manufacturing?

A2: Yes, we have long-term cooperation with many copper coated laminate suppliers, and we can contact the materials you are looking for.

Q3: What is the wrong hole in the HDI board ? Why break?

A3: It means that the two layers of mechanical holes are misaligned. Because the copper plating is not done, the inside of the hole is empty, so it is not possible to drill a hole directly into it.

A1: We are a professional HDI PCB manufacturer. We have many years of experience in PCB manufacturing. We check the quality of incoming materials layer by layer to ensure product quality. We have long-term cooperative brand suppliers such as Shengyi, Lianmao, Taiyao, Rogers.... The production process strictly controls each process and complies with international PCB quality system standards.

Q2: Can you specify the materials for PCB manufacturing?

A2: Yes, we have long-term cooperation with many copper coated laminate suppliers, and we can contact the materials you are looking for.

Q3: What is the wrong hole in the HDI board ? Why break?

A3: It means that the two layers of mechanical holes are misaligned. Because the copper plating is not done, the inside of the hole is empty, so it is not possible to drill a hole directly into it.

Hot Tags: HDI PCB, China, Factory, Manufacturers, Suppliers, Price, Made in China

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Related Products

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy