English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

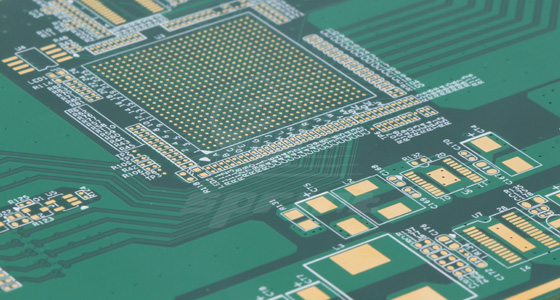

Industrial PCB circuit board manufacturer

2024-12-12

Industrial PCB manufacturing is an industry that has extremely high requirements for precision, reliability and durability. Among many manufacturers, evaluating the technical level and production capacity of an industrial PCB manufacturer is the key to ensuring product quality and meeting industrial needs. The following will discuss how to evaluate the technical level and production capacity of an industrial PCB manufacturer.

The evaluation of the technical level and production capacity of industrial PCB manufacturers can be carried out from the following key dimensions:

1. Design capability: Evaluate whether the manufacturer has advanced circuit design capabilities, including high-density circuit layout, signal integrity analysis, and electromagnetic compatibility design. Design capabilities are directly related to the performance and reliability of PCB.

2. Production process: Investigate whether the manufacturer's production process is advanced, including but not limited to precision drilling technology, high-precision photolithography, and modern surface mounting technology (SMT). The maturity of these processes directly affects the quality and consistency of the product.

3. Material selection: Materials are the basis for determining PCB performance. Evaluate whether the manufacturer selects high-standard materials, such as high-performance substrate materials, conductive copper foil, and surface treatment materials, which are important for the electrical performance and environmental adaptability of PCB.

4. Quality control system: The manufacturer's quality control system is the key to ensuring product stability. Evaluate whether the manufacturer has established a complete quality control process, including incoming material inspection, process control, and final product testing.

5. Production equipment: Advanced production equipment is the prerequisite for achieving high-precision manufacturing. Investigate whether the manufacturer has modern production equipment, such as automated production lines, high-precision drilling and milling machines, and automatic optical inspection equipment.

6. R&D investment: Technological innovation is the core driving force for the development of the industry. Evaluate the manufacturer's investment and achievements in new technology research and development, new material application, and new process exploration.

7. Customer feedback and cases: Customer feedback and success cases in actual applications are direct evidence for evaluating the strength of manufacturers. Understand whether the manufacturer has long-term large industrial enterprise customers and their satisfaction with product performance and services.

8. Environmental protection and sustainable development: With the improvement of environmental awareness, evaluate whether the manufacturer pays attention to environmental protection in the production process, whether it adopts green production methods, and whether it has a sustainable development strategic plan.

The technical level and production capacity of industrial-grade PCB circuit board manufacturers are important indicators to measure their market competitiveness. Through the comprehensive evaluation of the above multiple dimensions, we can fully understand the strength of the manufacturer and choose partners who can provide high-quality products and services. With the continuous advancement of Industry 4.0 and intelligent manufacturing, industrial-grade PCB circuit board manufacturers will continue to play a key role in technological innovation and production capacity improvement, and contribute to industrial automation and intelligence.